Bijur Delimon AirMax Air Oil Lubrication System

Increase Chain Life & Improve Performance with Air Oil!

STATE OF THE ART AIRMAX AIR OIL LUBRICATION SYSTEM

FOR CHAIN CONVEYOR APPLICATIONS

- Significantly increases chain life.

- Reduced chain wear improves accuracy and provides better performance.

- No sophisticated controls required. Fully stand alone with on-board timer or ties into existing controls.

- Environmentally friendly. Reduces waste.

- Optional enclosures available for “wash down” (CIP) conditions.

- Increased output and production up-time.

- Precise delivery.

- Prevents bearing contamination.

- Cooling of lubricated parts.

- Unmatched lubricant delivery accuracy.

- Includes low oil switch, integral timer with optional oil pressure switch.

Replace Oil Mist and Go Green with Air Oil!

STATE OF THE ART AIRMAX AIR OIL LUBRICATION SYSTEM

FOR HIGH SPEED SPINDLE APPLICATIONS

- Easily replace your existing Mist System including Norgren, Alemite, SMC, Taco, and many more.

- Environmentally friendly. Reduces waste. No mist clouds or fog.

- Reduction of spindle vibration, operating temperatures, lubricant cost, and air usage.

- Significantly increases bearing and spindle life.

- Fully stand alone with on-board timer or ties into existing controls.

- Lower maintenance.

- Increased output and production up-time.

- Precise delivery.

- Prevents bearing contamination.

- Cooling of lubricated parts.

- Unmatched lubricant delivery accuracy.

- Includes low oil switch, integral timer with optional oil pressure switch.

- Full monitoring capabilities, available with Oil Streak sensor 1~4 outlets.

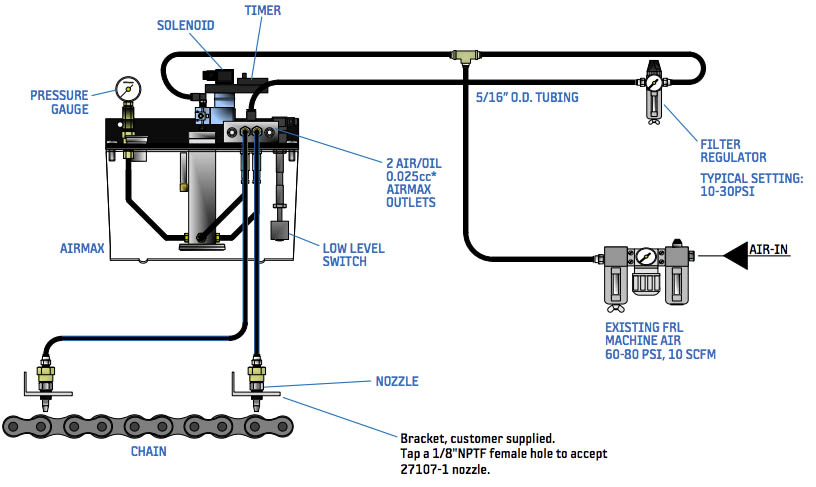

AirMax — Pneumatic Pump

The AirMax is a simple economical lubricator, ideally suitable for air-oil systems. The AirMax is supplied with a 3 liter reservoir, pressure gauge and oil inlet filter with the options of an oil pressure switch, low level switch, solenoid valve and timer.

The AirMax comes complete with a pumping unit and a integrated air-oil injection system. The required number of oil injectors and the delivery on each port can be selected from the smart number.

The AirMax includes an air actuated, spring return piston pump. The inlet air pressure supply to the pumping element determines the output oil pressure. When used with positive displacement injectors (PDI) the minimum oil pressure should be 260 PSI (18 bar).

For extended service, incoming air must be dry. Always use a suitable FRL unit (filter/regulator lubricator) to control the inlet air supply to the pumping unit (set air to recommended operating pressure). The AirMax pumping unit is cycled using a 3/2-way solenoid valve (typical cycle; 5 seconds “on” and 30-300 seconds “off”).

A continuous air supply is required to the air-oil injection block and it should be separately regulated to control the air-oil flow rate to the lube point.

Other Applications:

- Chain (Roller or Conveyor)

- Bakery Cooling Towers

- Centrifuge