Bijur Delimon Heavy Duty Electric Barrel Pump

Grease & Fluid Grease

FEATURES & BENEFITS

- Available for progressive, dualine, and/or injector lubrication systems.

- Rugged construction for outdoor use and rough environments.

- Eliminate expensive air consumption.

- Longer life expectancy – last barrel pump you will have to buy!

- Fits standard 120lb / 50kg and 400lb / 185kg grease drums.

- Extremely low noise levels – work right next to it.

Adding a Bijur Delimon lubrication system increases equipment life by decreasing wear on vital components. Automatic lubrication systems safely and continuously supply lubricant while your machine is running.

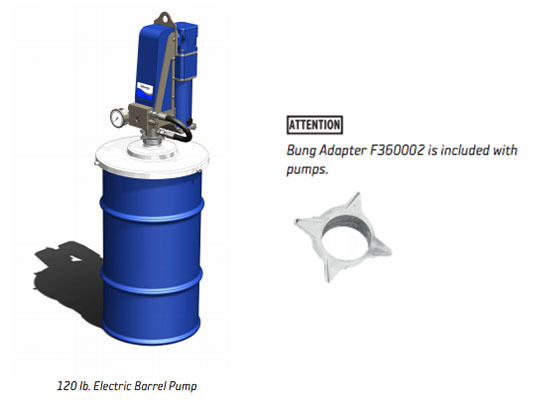

ELECTRIC BARREL PUMP

Bijur Delimon’s AC or DC Electric Barrel Pumps will replace the air or hydraulic operated pumps now used for lubrication system on mobile or stationary equipment. Installation is cleaner – no air or hydraulic lines to install/leak. Simply wire into the machine's power supply. Pressure rated to 300 bar (4350psi). Will fit original refinery 120 and 400lb drums (50kg & 185kg). Drum cover and follower plates also available.

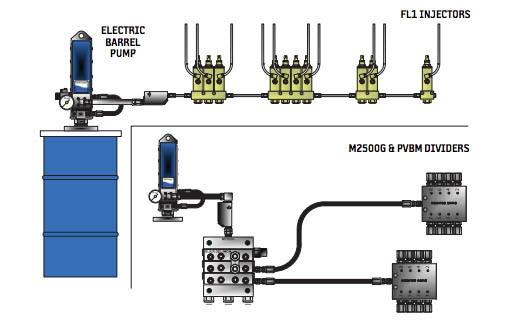

Bijur Delimon’s new state of the art Electric Barrel Pump's versatility is unmatched in the market today. As seen below the new EBP can operate all styles of lubrication systems and metering from progressive, injector, direct, and even dualine. Versions are also available for all standard drum sizes. Now you can standardize on one pump design throughout your plant!

OPERATION

The pump end (bottom) consists of a hardened steel bushing, through which the piston runs. As the piston strokes down, grease is pushed past the check valve ball and out through the extruded discharge holes in the pump stem. As the piston strokes up, the check valve prevents drawback, and a vacuum is created inside the bushing. When the piston uncovers the suction holes in the bushing, another charge of grease is drawn in through the suction ports on the bottom of the stem and into the bushing. The cycle then repeats.

TECHNICAL DATA

| Standard Tube Lengths/Fits Drum Size 1 | 120 lb. (50 kg), 400 lb. (185 kg) | |

| Voltages | 24 VDC | |

| 115/230 VAC (50/60 Hz) Single Phase | ||

| Amp Draw | 24VDC 2 | 15 Amp draw @ 3500psi 20°C (68°F) with NLGI #2 |

| 115VAC 3 | 4 Amp draw @ 3500psi 20°C (68°F) with NLGI #2 | |

| 220VAC 4 | 2 Amp draw @ 3500psi 20°C (68°F) with NLGI #2 | |

| Lubrication Flow 5 | 150cc/minute @ 140 bar, +20°C (9 cu.in. @ 2030 psi, +68°F) | |

| Pump Pressure | 300 bar max/240 bar recommended (4350psi / 3480 psi) | |

| Systems 6 | Progressive | Pressure Relief Valve Included |

| Injector | Vent Valve & Pressure Relief Valve Included | |

| Relief Valve Pressure | 240 bar / 3500 psi | |

| Vent Valve Voltages | 24 VDC | |

| 115/230 VAC (50/60 Hz) Single Phase | ||

| Operating Temperature 7 | -25°C to +60°C (-13°F to +140°F) | |

| Pressure Gauge | 350 bar Included (5000 psi) | |

| Lube Outlet Port | 1/2” NPSF (F) | |

| Lubricants 8 | NLGI #000 to #2 | |

| Rating | IP66 | |

| Noise Level 9 | 75dB | |

1 Bung Bushing F360002 is included with pumps.

2 16 Amp draw spike. Recommend 40A fuse max.

3 5 Amp draw spike. Recommend 7A fuse max.

4 2.5 Amp draw spike. Recommend 4A fuse max.

5 Flow rate is for 60 Hz motors. 60 Hz motor can operate on 50 Hz but pump flow is reduced.

6 Suitable for Dualine system when paired with a hydraulic or electric reversing valve.

7 Lower temperatures may be possible with suitable grease and/or heated reservoir/piping.

8 EBP will also work pumping oils.

9 Noise level measured at 3’ (1 m) from the pump.

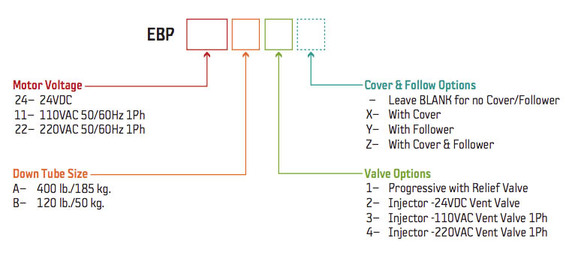

HOW TO ORDER

When ordering, specify by name, description and part number, e.g. Electric Barrel Pump, 24 VDC,

120 lb Down Tube, Progressive with Cover & Follower, Part #EBP-24B1Z.

Refer to the following documents: Catalog #33136: Industrial Lubrication Products

ACCESSORIES

| Photo | Description | Part # | |

|---|---|---|---|

|

Hose Assemblies 345 bar/5000 psi WP 1/2”I.D. Hose X 3/4-16 SAE female ends |

72”-IN LG | 200549 |

| 144”-IN LG | HOS13907B | ||

|

STR Male Adapters for hoses (Additional sizes in Catalog 151) |

3/4-16 x 1/2NPT 3/4-16 x 3/8NPT 3/4-16 x 1/4NPT |

U43188 U43168 U43148 |

|

Drum Covers

* Order with Adapter F360133 |

120 LB | F418017* |

| 400 LB | F418026* | ||

|

Follower Plates | 120 LB | F964 |

| 400 LB | F966 | ||

|

Level Switch Kits | 120LB NEMA 1 | LC10243 |

| 400 LB NEMA 1 | LC11036 | ||

| 120 LB NEMA 4X | LC13689C | ||

| 400 LB NEMA 4X | LC13689C-1 | ||

|

Empty Drum Containers | 120 LB | 37153 |

| 400 LB | 36490 | ||

|

Drum Blanket Heaters | 120 LB | 37506 |

| 400 LB | 55286 | ||

|

Pump Hoist | F391022 | |

|

Grease Handles with Meter 1/4”NPTF |

F1177 | |

|

Pump Tie Down Kits | 120 LB | F2440 |

| 400 LB | F2450 | ||

|

Bung Seal Kit | F2449 | |