Turcite® B Slydway® - Technical Data: Typical Properties

| Mechanical Properties | Test Method | Metric | Imperial |

|---|---|---|---|

| Specific Gravity | ASTM D792 | 2.0 - 2.4 | 2.0 - 2.4 |

| Tensile Strength | ASTM D4745 | 13.8 MPa | 2002 psi |

| Tensile Elongation at Break | ASTM D4745 | 100% | 100% |

| Hardness | ASTM D2240 | 50 - 60 Type D | 50 - 60 Type D |

| Peel Strength (Bonded to metal substrate using Waylock® II Adhesive) |

TSS Internal | 178 N /mm | 40 lbf /in |

| Compressive Strength | ASTM D695 | ||

| 0.2% Offset | 7.6 MPa | 1102 psi | |

| 1% Strain | 6.1 MPa | 885 psi | |

| 5% Strain | 13.2 MPa | 1915 psi | |

| Youngs Modulus | 722 MPa | 105 ksi | |

| Deformation Under Load | TSS Internal | ||

| 2 kg/cm2 @ 0.203 mm/min | 0.016 mm | ||

| 4 kg/cm2 @ 0.203 mm/min | 0.030 mm | ||

| 6 kg/cm2 @ 0.203 mm/min | 0.043 mm | ||

| 28 lb/in2 @ 0.008 in/min | 0.0006 in | ||

| 57 lb/in2 @ 0.008 in/min | 0.0012 in | ||

| 85 lb/in2 @ 0.008 in/min | 0.0017 in | ||

| Thermal Properties | |||

| Coefficient of Linear Thermal Expansion | ASTM E831 | ||

| 25°C to 100°C | 103.5 µm/m°C | ||

| 100°C to 150°C | 135.7 µm/m°C | ||

| 77°F to 212°F | 57.5 µin/in°F | ||

| 212°F to 302°F | 75.4 µin/in°F | ||

| Thermal Conductivity | TCi Thermal Analyzer | ||

| 23°C | 0.36 W/m-k | ||

| 73.4°F | 0.36 W/m-k | ||

| Tribological Properties | |||

| Wear Factor, K: Lubricated, Tonna V68 Way Oil | TSS Internal | 3.57 E-08 mm3/Nm | 2.47 E-13 in3/lb-in |

| Friction Coeffiecient: Lubricated, Tonna V68 Way Oil | TSS Internal | 0.034 | 0.034 |

| Color Description | |||

| Turquoise bronze |

Turcite B - Physical Properties

| Property | Units | Test Method | Value |

|---|---|---|---|

| Tensile Strength | PSI | ASTM D4894 | 2000 min |

| Tensile Elongation | % | ASTM D4894 | 170 min |

| Specific Gravity | - | ASTM D792 | 3.10 |

| Hardness | Shore D | ASTM D2240 | 50-60 |

Coefficient of Friction

-

Testing data from testing completed at Corporate R&D

|

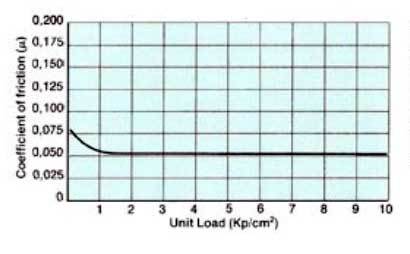

Friction as function of unit load Lubricated friction - Velocity 2 m/min (6,6 ft/min.) Materials: Turcite B (Scraped) Cast iron (Scraped) |

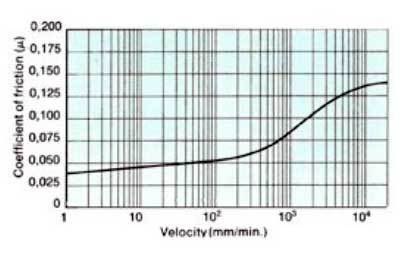

Friction as function of velocity Dry friction - Loading 3.5 Kp/cm2 (50 psi) Materials: Turcite B (Fresh) Cast iron G.S. 55, 264H8, (Ra=0,47) ( 19 CLA) |

|

|

|

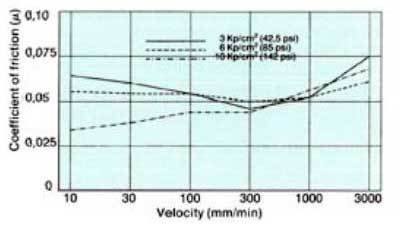

Friction as function of velocity after 0 Krn travel Lubricated with oil 5ºE Materials: Turcite B (Scraped) Cast iron G26 (Ra=0,8) (32 CLA) |

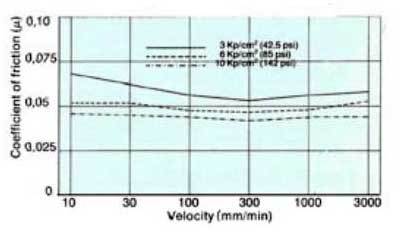

Friction as function of velocity after 40 Km travel Lubricated with oil 5ºE Materials: Turcite B (Scraped) Cast iron G26 (Ra=0,8) (32 CLA) |

|

|

-

In the application, Slydway displays only a slight difference between static and dynamic friction, thus eliminating any presence of stick slip.

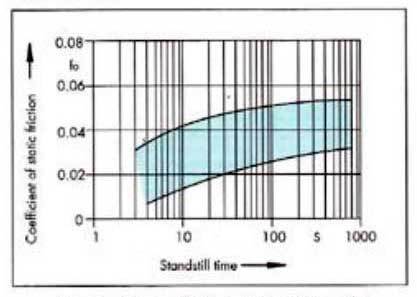

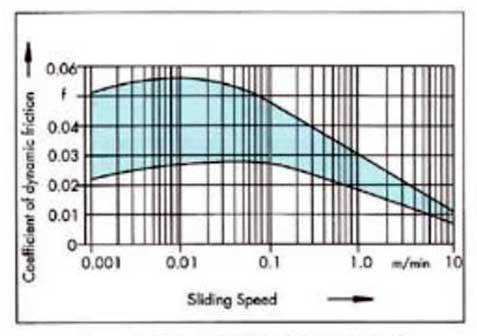

| Figure shows the range of static friction when using different oils. The values were determined on a scraped Turcite®-B sliding surface with a surface contact pressure of 35 N/cm2 and a surface roughness of the guide of Ra=0.6 µ.m. | Figure shows the least differences at the transition to the hydrodynamic range. With higher surface pressures of up to 200 N/m2, the sliding behaviour changes only insignificantly. Good lubrication is of paramount importance in order to achieve a controlled level of dynamic friction. |

|

|

| Range of the coefficient of static friction (fp) as a function of the standstill time when using different lubricants. | Range of the coefficient of dynamic friction (f) as a function of the sliding speed when using different lubricants. |

Wear

-

Testing data from testing completed at Corporate R&D

-

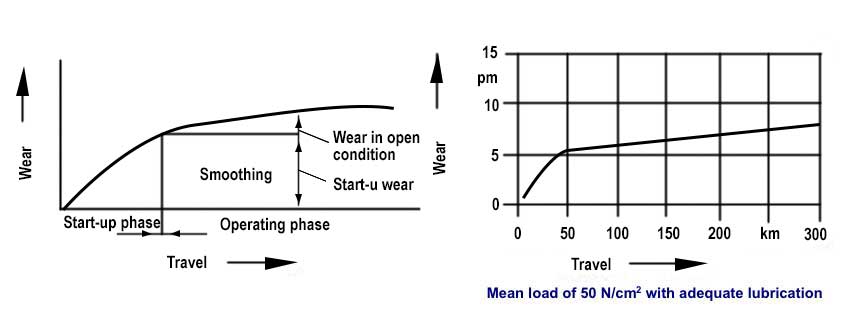

Turcite B Slydway should always be well lubricated during the start-up phase. Very fine particles of the Turcite B Slydway are transferred to the mating surface during the start-up phase.

-

This leads to the slight shading of the metallic mating surface.

-

The start-up phase is concluded with the smoothing phase.

-

-

After the smoothing phase, Turcite B Slydway will experience a low level of both the wear and friction, thus essentially remaining constant.

-

Testing data from testing completed at Corporate R&D

|

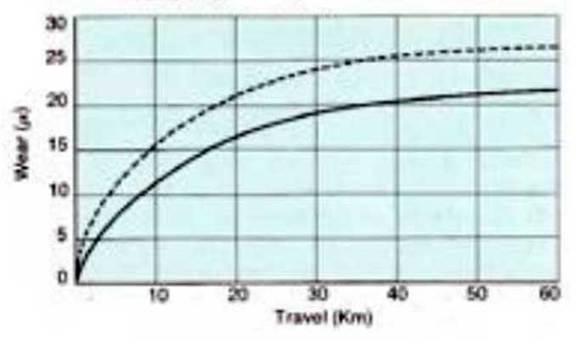

Wear as function of travel Lubricated friction - Loading 6Kp/cm2 (85 psi) Materials: Turcite B (Scraped) Cast iron G26 (Ra=0.8) (32 CLA) |

Wear as function of travel Dry friction - Loading 20 Kp/cm2 (284 psi) Materials: Turcite B Steel C60 (Rt=3µ) --------------- Cast iron (Rt = 3µ) _____________ |

|

|

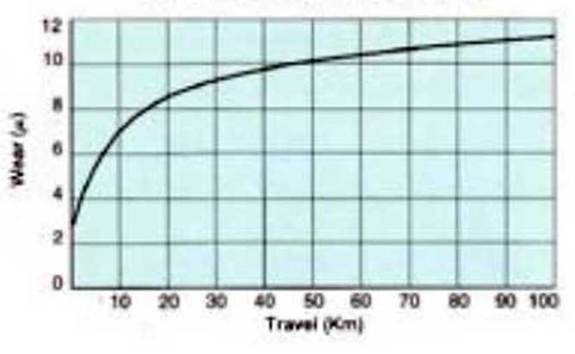

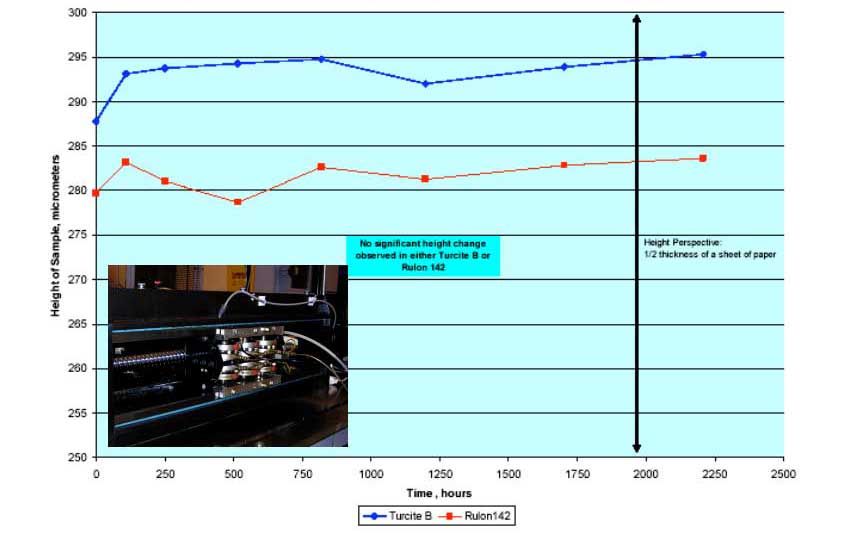

Wear - Comparison between Turcite B Slydway & Rulon 142

|

Height of Rulon 142 and Turcite B Samples During Lubricated Test 50psi, WayLube Oil Reciprocating Test but Specimens change Speed and Direction (Velocity) Multiple Times per Cycle |

|

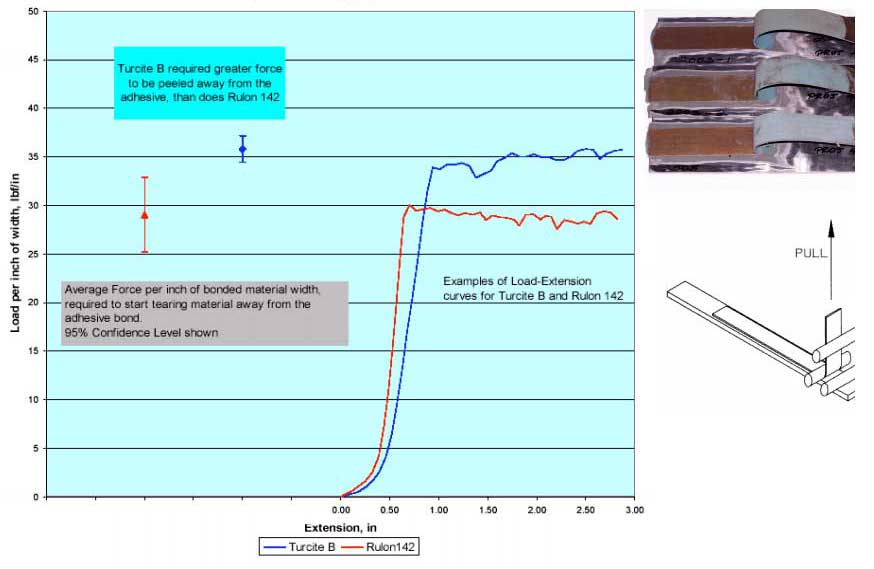

Peel Strength Comparison between Turcite B Slydway & Rulon 142

|

Peel Tests on Turcite B Bonded with Waylock II Adhesive, and Rulon 142 bonded with CE211 Material Strip Pulled at 2"/minute |

|

For more information on Turcite B, download our Technical Data Sheet.